In the face of mounting water scarcity challenges, integrating Internet of Things (IoT) solutions has become crucial for sustainable water management in various industries. These challenges, ranging from increased operational costs to global trade disruptions, necessitate innovative approaches to water monitoring and management.

The Role of IoT in Water Management

IoT devices, particularly water level and quality sensors, are proving instrumental in addressing both short-term and long-term impacts of water scarcity. These sensors provide real-time data crucial for industries like agriculture, manufacturing, and utilities, where water usage directly impacts productivity and operational costs.

Understanding Modbus in IoT Integration

Modbus, a communication protocol widely used in industrial environments, plays a vital role in the integration of IoT devices. It is a method for devices to communicate over digital networks and is known for its simplicity and reliability. By connecting IoT water level sensors to a system via Modbus, industries can automate processes and make more informed decisions based on real-time data.

Embracing IoT for Advanced Water Management in Industry

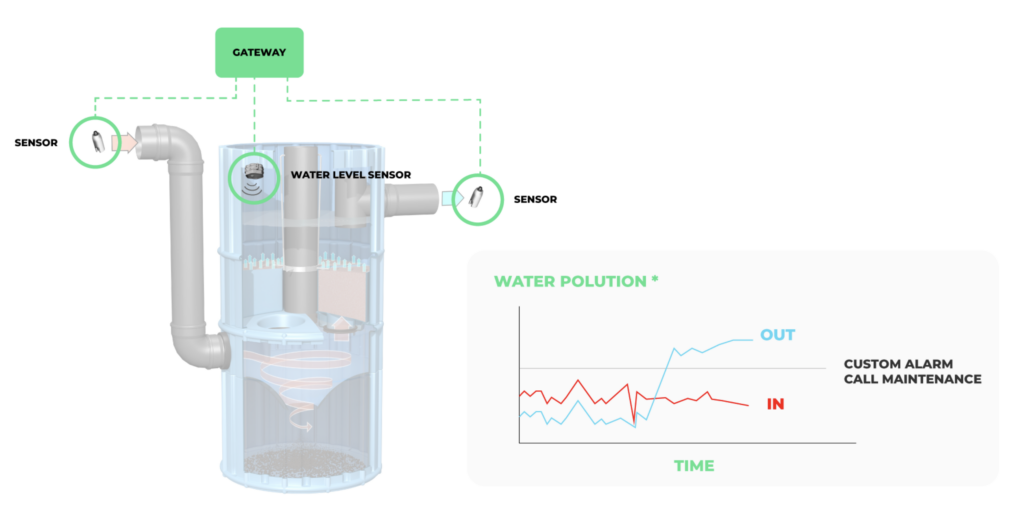

In the complex world of industrial manufacturing, precise control over water levels and quality is not just a matter of efficiency—it’s a necessity for operational continuity and environmental stewardship. The shared image illustrates a sophisticated IoT water management system that’s up to the task.

At the core of this system are IoT water level sensors, diligently monitoring the water within tanks. Connected to a plant’s control system via the Modbus protocol—a communication standard that facilitates data transfer between equipment and control devices—these sensors enable a highly responsive automation framework. When water levels hit critical thresholds, whether too high or too low, the system springs into action, triggering processes like activating pumps or opening valves to correct the imbalance, ensuring water levels are maintained within optimal parameters.

Furthermore, the IoT sensors are equipped to measure an array of qualitative parameters, such as pH, turbidity, and concentrations of NO2 or NO3. Monitoring these parameters is crucial across various industries, where the quality of water used can have direct implications on product quality and compliance with environmental regulations. When these sensors detect any deviation from the set standards, they can trigger alert notifications, prompting immediate maintenance actions.

This image encapsulates the automation that IoT brings to industrial water management, showcasing how efficiency and conservation go hand-in-hand. Through such smart systems, industries can achieve heightened control over their water usage, ensuring both resource sustainability and adherence to quality standards. This is the future of industrial water management—smarter, more connected, and responsively automated.

As industries navigate the economic implications of water scarcity, the integration of IoT solutions, supported by reliable communication protocols like Modbus, is key to ensuring sustainability. This approach not only helps industries reduce operational costs but also plays a pivotal role in enhancing overall efficiency and contributing to environmental conservation.

Leave a Reply